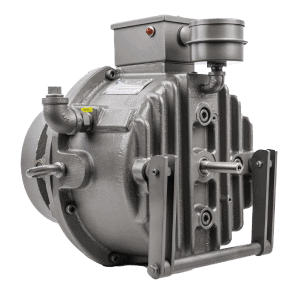

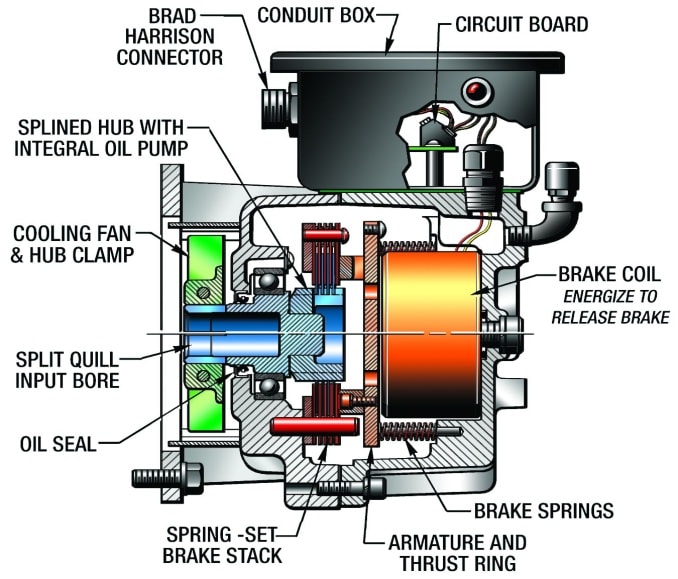

Designed with Oil Shear Technology the MagnaShear Motor Brakes typically mount to the back of a brake motor. They are designed to be a stopping brake, not just a holding brake.

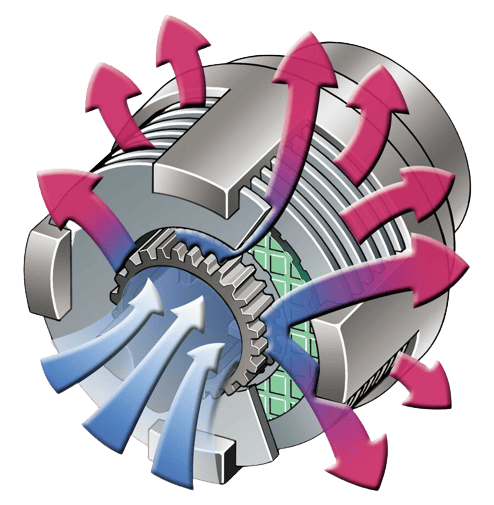

Oil Shear Technology, perfected over 50 years by Force Control Industries, allows the brake to dynamically slip to a stop without wearing friction material, and the fluid circulating through the brake friction stack transfers the heat of engagement to the housing to be cooled. This allows the brake to operate at a consistent torque for many years without adjustment, or maintenance.

They can survive the harsh environments of mining, manufacturing, material handling as well as packaging and food processing with minimal maintenance and no adjustment. The totally enclosed rugged housings keep dirt and moisture out while reducing noise and extracting heat.

Dry friction brakes are typically designed as holding brakes. Using them for dynamic stopping wears friction material away causing constant adjustment and frequent replacement of discs, pads, or shoes.