Selecting the Correct Posistop Stopping Brake

Using Inertia, Cycle Rate, Duty Cycle, Speed and Efficiency

There are many pieces to selecting the correct stopping brake for a particular application. It uses many of the components of selection for gear reducers, chain and belt drives and motors, but has some very important differences.

To start the selection we must have some information of the application.

What is the application – type of machine, motion required, environment, vertical load up or down, acceleration and deceleration time, soft start, or high inertia load.

What is the cycle rate – how many indexes per minute, day, hour.

What is the duty cycle – time engaged vs time off

What is the torque requirement for stopping the load. They are often different.

There are two parts to determine the total torque required.

Cyclic Inertia – Cyclic inertia of all components to be decelerated must be determined and reflected back to the brake through the ratio. This would include the inertia of the driven component as well as the items in the drive train from the output shaft of the brake on. These could be shafts, couplings, gears, sprockets pulleys, flywheels, and more. Each component inertia should be calculated, and reflected back through the ratio to the brake output. Inertia on the input side of the brake is not involved.

Load torque – In addition to inertial torque load torque should be determined and added to the inertial torque. Load torque is the torque to overcome the load. Load torque could be weight such as lowering a load on a vertical conveyor or elevator. For instance a vertical conveyor will have a certain torque requirement just to hold the load. This must be added to the inertia torque. Friction can reduce the load torque when sizing a brake. Note the torque must be reflected through the ratio back to the brake.

Brakes should be sized for the required loads and not significantly oversized. Over sizing a brake can cause as many problems as under sizing. Over sizing, especially the brake, can add severe loads to all of the drive line components breaking couplings, belts or shafts.

System efficiency – Efficiency of all drive and load components must be included in the calculations. Typically they will deduct from the brake torque requirement.

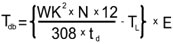

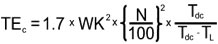

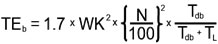

Thermal Horsepower – A second component for sizing is thermal energy, or heat that must be dissipated. In simple terms when the brake is engaged to stop the load all of the rotary motion energy is converted to heat in the brake. The thermal requirement for the brake must be calculated. This is normally shown as thermal horsepower in the specifications.