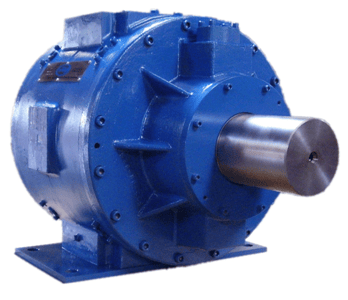

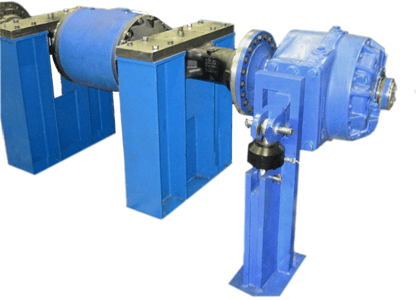

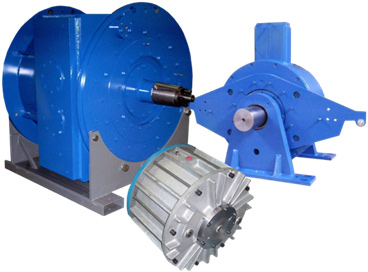

Positorq Tension Brakes

- Steel strip, paper, wire

- 50 Lb. Ft. to 200,000 Lb. Ft. Continuous tension

- Up to 3000 Thermal HP.

- Linear control based on pressure

- Quick Response – Smooth Quiet Operation

- Dynamic Stopping Capability for Set or E-Stop

Smooth, Quiet, Control, With E-Stop Capability

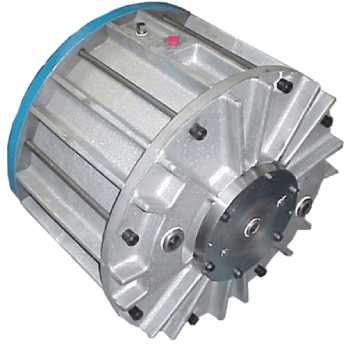

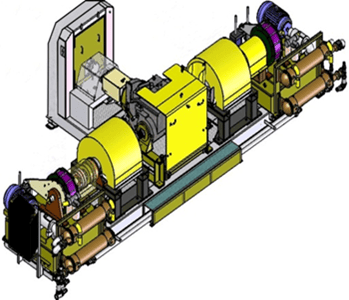

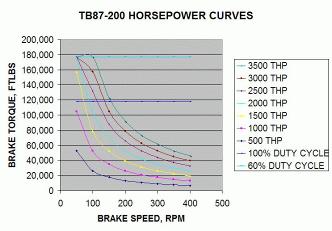

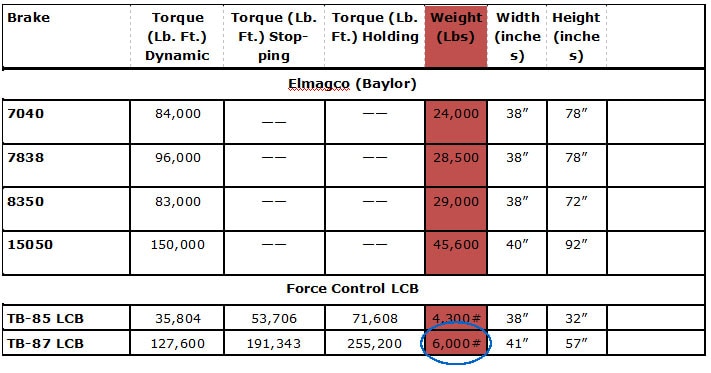

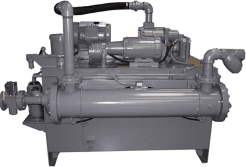

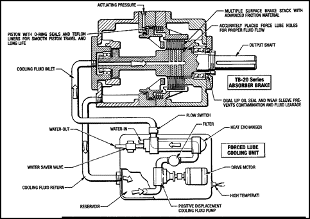

The Positorq Oil Shear absorber brakes are a unique design for continuous tension control, The unique Oil Shear Technology provides extremely smooth, ultra quick response, negligible wear with no adjustment required, high energy dissipation in a compact package, and noise free. Positorq Brakes are rated up to 200,000 Lb. Ft. Slip Torque and 3000 Thermal Horsepower.

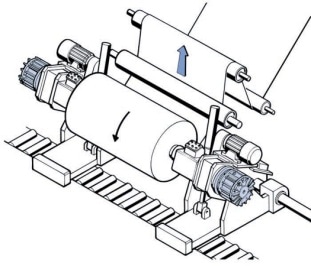

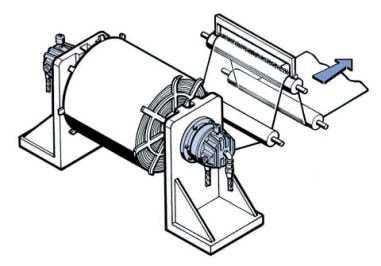

The Positorq brakes work well in tension applications, especially unwind stands, where the brake is used to maintain tension on the strip. This can be paper, board, plastic, copper, steel and wire stands. The brake can be coupled, flange mounted or connected through gear, belt, or chain drive.

A major advantage for Positorq brakes is Oil Shear Technology. Oil Shear Technology provides smooth engagement, higher heat dissipation, negligible wear on friction discs, bearings, and splines, and quiet operation.

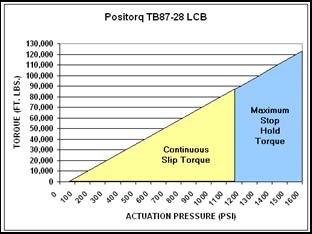

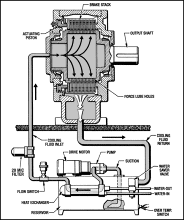

The Positorq Brakes operate by applying pressure on a piston or pistons clamping the friction stack. The tighter the clamping force the higher the torque, and it is not affected by speed. The actuation medium can be pneumatic or hydraulic. The hydraulic actuation is more controllable.

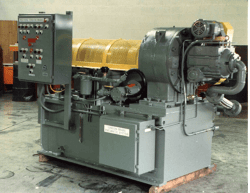

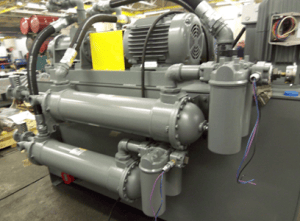

Transmission fluid in the brake transmits torque between the friction disc and drive plates providing the torque. As this fluid is heated it is pumped back through a Forced Lube Cooling Unit that has oil-to-water or oil-to-air cooling, filters, pumps and reservoir. The FLCU allows the brake to be very compact, with low inertia.

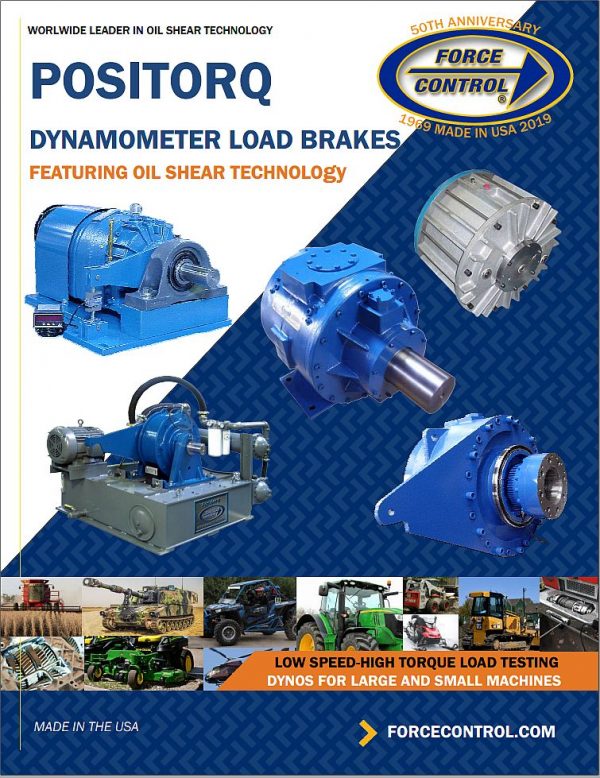

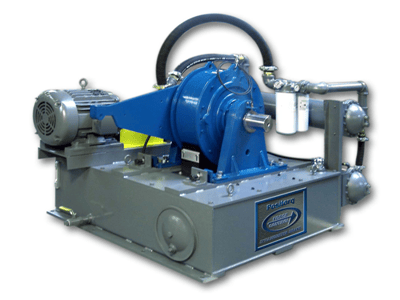

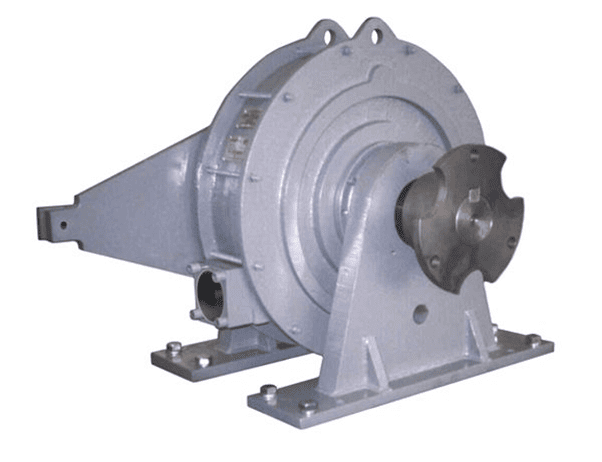

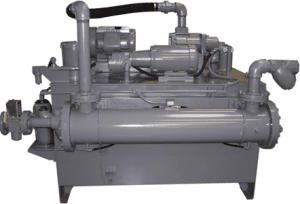

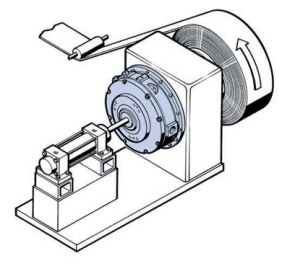

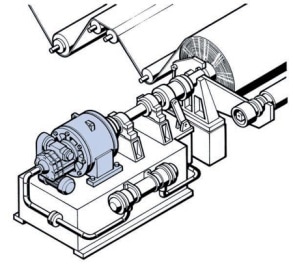

Positorq Dynamometer Load Brakes

- Low Speed High Torque Load Testing

- Final drive, transmissions, axles

- Direct connect to test item – no speed up drive

- 50 Lb. Ft. to 180,000 Lb. Ft. continuous tension

- Up to 3000 Thermal HP.

- Linear control based on pressure

- Quick Response – Smooth Quiet Operation

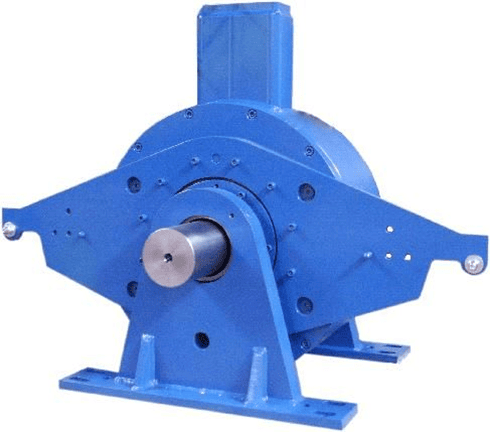

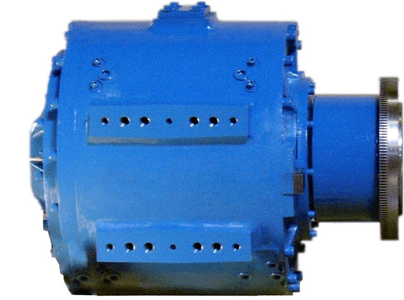

Designed for High Torque – Low Speed Load Testing

of Axles, Final Drives, and Transmissions

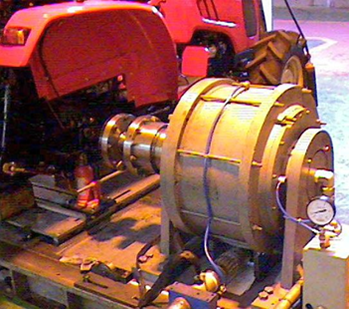

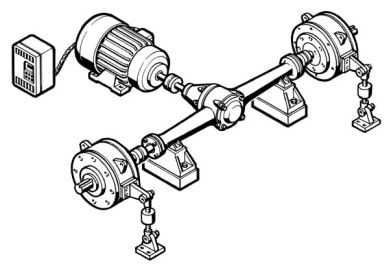

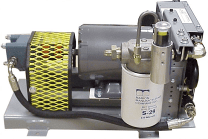

Whether it’s testing the most complex aircraft system, off road final drives, or tractor transmissions; Force Control has the products for your load testing requirements. Our patented high-torque, low-speed Positorq load brakes are used to simulate real world environments.

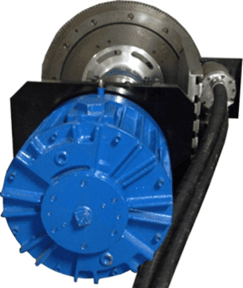

Force Control Industries unique Oil Shear Technology provides heat dissipation for high horsepower applications while maintaining a compact profile capable of direct mounting to the drive axle – eliminating additional gearboxes.

In addition, with Oil Shear Technology, disc wear is negligible, allowing long term testing without loss of torque. In fact most Positorq Dynamometer load brakes in service over the past 40 years have required little to no maintenance.

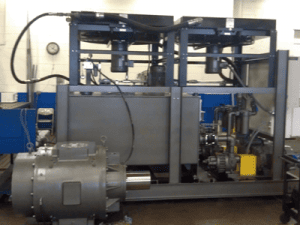

HIGH TORQUE – LOW SPEED Load Testing

Why Select Positorq Dynamometer Load Brake

- Quick Response

- Proportional Linear Torque Control

- Continuous High Torque at Low Speed

- High Static Torque

- No Chatter Down to 0 RPM

- Quiet—Less Than 20 dB

- Compact Size—Direct Axle Mount

- Air or Hydraulic Actuation

- Extremely Long Service Life

- Near Zero Hysteresis

- Torque up to 300,000 Lb. Ft.

- Dissipating up to 3000 HP

- Variety of Mounting Types