Fiberglass insulation, essential in construction and industry, is made by blending sand, limestone, soda ash, and recycled glass cullet with up to 50% recycled content. This eco-friendly material offers businesses both sustainability and high performance, reducing environmental impact and enhancing efficiency for industries prioritizing thermal regulation.

At Force Control Industries, we specialize in fiberglass insulation batt applications, particularly in chopping and folding processes. Our solutions ensure precise and efficient operations, optimizing production and elevating product quality to confidently meet the insulation industry’s demands.

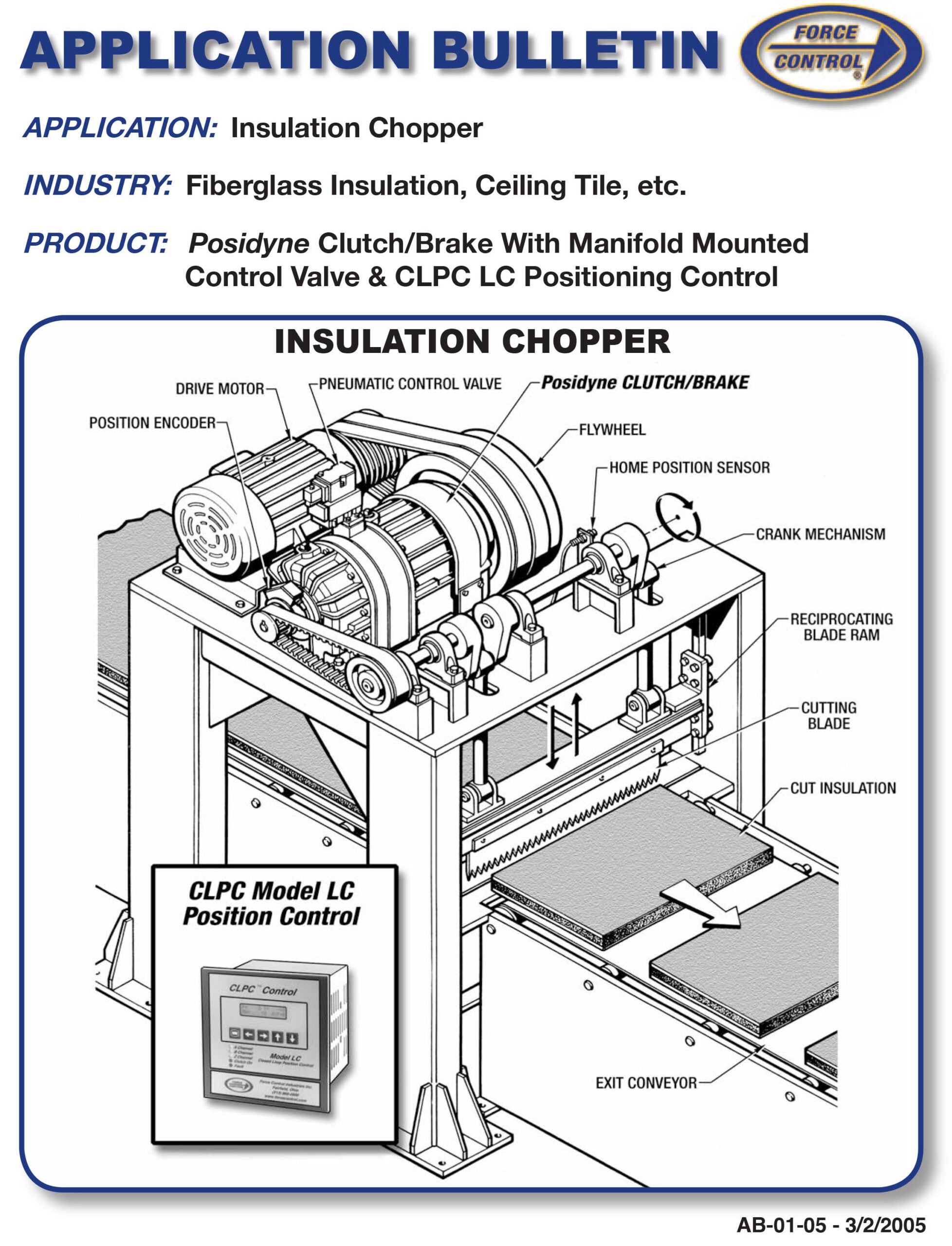

Insulation Chopper

Force Control Industries offers cutting-edge insulation choppers tailored for the fiberglass and ceiling tile industries. This product integrates the Posidyne® Clutch/Brake system with a manifold-mounted control valve, optical encoder and CLPC LC Positioning Controller, setting a new benchmark for efficiency and reliability in insulation manufacturing.

The Posidyne Clutch/Brake with Manifold Mounted Control Valve & CLPC LC Positioning Control optimizes cutting for fiberglass insulation, batting, and ceiling tiles. It ensures precision and efficiency in manufacturing and delivers seamless, accurate cuts, elevating production quality and efficiency.

How They Work

Fiberglass and other insulation materials are made continuously and conveyed down a long cooling conveyor. At the end of the cooling conveyor, a guillotine-type cut-off device is used to cut them to length. The chopper is a horizontal blade driven by crank arms, accelerating the blade downward (or upward) through the material and back up (down) to a stop position. The CLPC LC receives a signal to index from the PLC or length counter and engages the clutch. When this count is met, the CLPC LC engages the brake, and the drive stops in position.

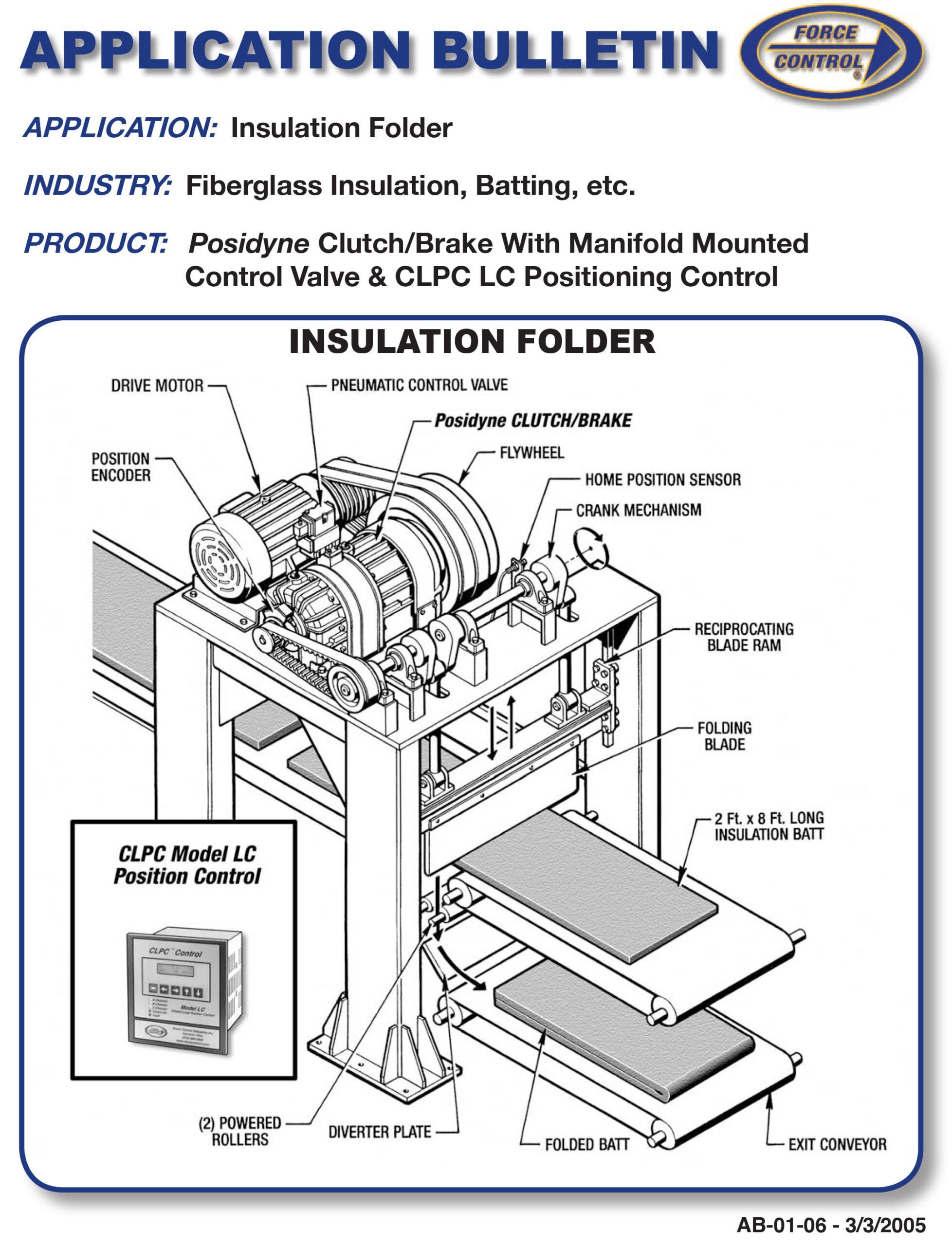

Insulation Folder

At Force Control Industries, we carry and also offer solutions for insulation folders. designed to transform insulation manufacturing. It offers efficiency for industries like fiberglass insulation and ceiling tile production.

Insulation folders are crucial in manufacturing fiberglass insulation or batting and other materials in a guillotine-type folder. Whether in insulation factories or related production facilities, they streamline the manufacturing process.

How They Work

Insulation folders play a vital role in continuous insulation manufacturing. Fiberglass and other materials are conveyed down a cooling conveyor and folded at the line’s end. Using a guillotine-type folding device, the process transforms large batts into manageable sizes for further processing. Driven by horizontal blades and crank arms, the folder ensures precise and efficient folding, streamlining production.

Problems Solved

These are the problems addressed by our insulation chopper:

- consistent acceleration for cut length accuracy

- stop positioning accuracy critical to length accuracy

- quick cutting and backing out of material to avoid bunching or buckling

- quick and easy adjustment of the stopping position of the crank

- elimination of overlap of clutch and brake unit causing additional drag and wear

- high maintenance and loss of production due to wear and failures

Key Features

Force Control Industries’ insulation chopper employs cutting-edge Oil Shear Technology, which utilizes transmission fluid for smooth acceleration, deceleration, and stopping. This minimizes wear and heat, extending the chopper’s lifespan and enhancing operational efficiency.

Additionally, small diameter friction surfaces and an output shaft minimize cyclic inertia, while a manifold-mounted valve enables swift response times. The CLPC LC system provides precise stops, digital position adjustment, and onboard diagnostics for streamlined maintenance, enhancing operational accuracy.

Force Control Industries: Your Experts in Fiberglass Insulation

At Force Control Industries, we specialize in fiberglass insulation batt applications, particularly chopping and folding processes. We guarantee precise and efficient operations, optimizing production and enhancing product quality.

Contact us today to learn more about how we can support your insulation manufacturing needs.