Built to Last, Guaranteed to Perform

Force Control Industries, Inc. manufacturers hazardous duty clutches and brakes for many conditions including wet, dusty or explosive environments as well as low temperature (-40C) applications.

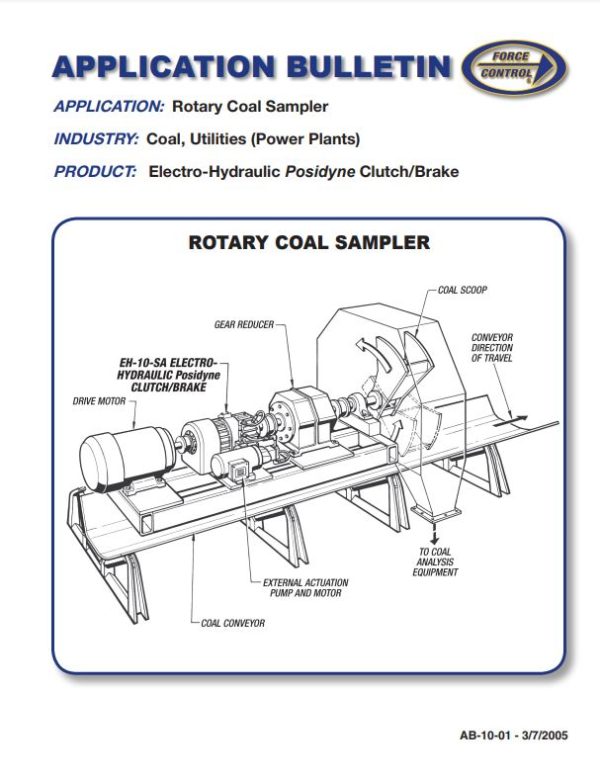

Clutches and Clutch Brakes: Posidyne

Force Control manufactures clutches and clutch brakes that are actuated either pneumatically or hydraulically. Air or hydraulic pressure is regulated and controlled via a solenoid valve. The totally enclosed, sealed housing (IP56 rated), makes the Force Control Posidyne clutch brake ready for many hazardous applications including dusty, dirty, and wet environments. Special modifications can be made for various specification requirements such as stainless steel fittings, nickel plated shafts or special coatings.

For explosion-proof applications, the units can be operated with air motors or explosion-proof electric motors. With an explosion-proof solenoid valve, the clutch brake can be used in many explosive environments including:

Classes I, II and III

Divisions 1 and 2

Groups A, B, C, D, E, F and G

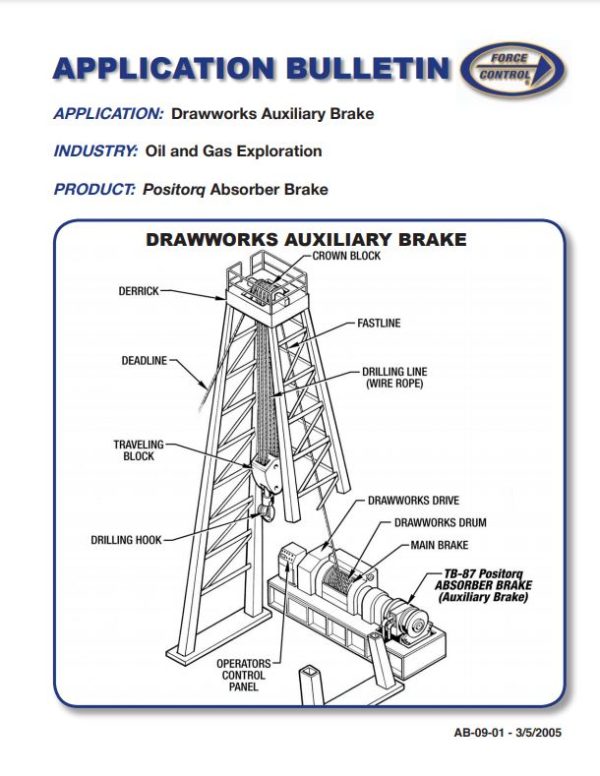

Pneumatic Brakes: Posistop

Force Control manufactures motor, coupler, tension and foot mounted brakes that are pneumatically or hydraulically actuated. These brakes can be Pressure-Set: Spring-Release or Spring-Set: Pressure-Release. Given the IP56 rated aluminum or cast iron housing, and with an explosion-proof solenoid valve, these brakes are suitable for the following hazardous environments:

Classes I, II and III

Divisions 1 and 2

Groups A, B, C, D, E, F and G

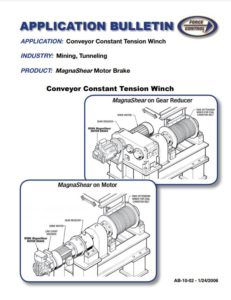

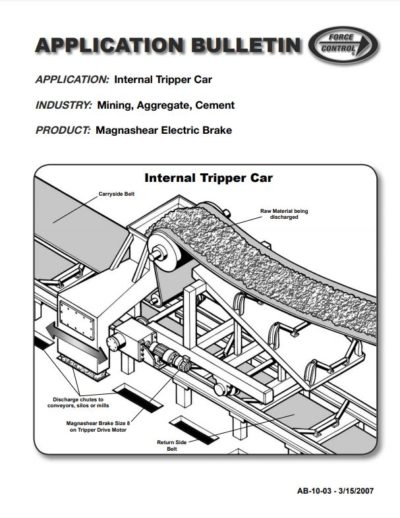

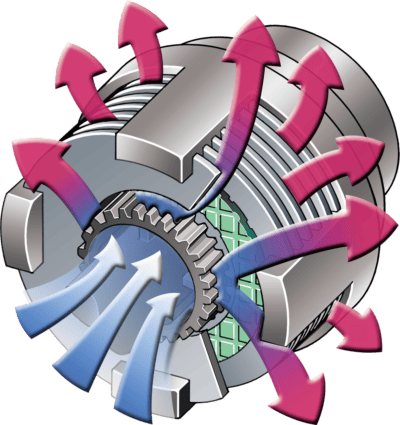

Electric Brakes: Magnashear (MHD Series)

Force Control manufactures fail-safe motor brakes that are Spring-Set: Electric Release with a 115 VAC coil option. Given the IP56 rated aluminum enclosure, and with an hazardous duty conduit box and potting epoxy, these brakes can be used in the following classifications: