Smooth, Controllable, Slipping, Stopping, and Holding All in One Brake

The Positorq brake can be used for three major types of applications:

- To supply constant tension for unwind applications in industries such as paper, foil, steel, coating, plating, etc.

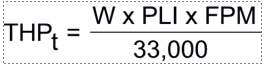

- As an energy absorber (Dynamometer) to create a known controlled load on a system, usually for testing purposes.

- Winch brakes to apply tension on the line is during unwind such as Drawworks auxiliary brakes, dynamic stopping and static holding.

How to Select a Positorq Tension Brake

The selection of a Positorq for a tension control application will vary depending on the type of tension application. The most common types of applications are:

- Constant Unwind -The parent roll is continuously unwound as for plating, coating, laminating, etc.

- Unwinding in Sets – The parent roll is wound onto several smaller rolls. In this application the parent roll will need to be stopped several times during the operation to change the smaller rolls.

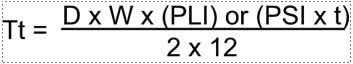

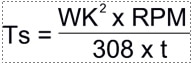

For a Constant Unwind application the two Torque Requirements to be considered are:

- The Torque to maintain constant tension.

- The Torque to stop the inertia of the roll for a panic stop.

When Unwinding in Sets, there are three Torque Requirements to be considered.

- The Torque to maintain constant tension.

- The Torque to stop the roll Inertia only, (E-Stop).

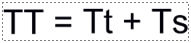

- The Total Torque to stop the roll Inertia and overcome tension at the first set stop.

The Total Torque Required when stopping at the first set stop is: (1)the total of the torque to maintain tension plus (2) the torque to stop the roll.

The larger of (1) The Total Torque required at set stop or (2) The Torque required for a Panic

Stop, should be used for selection purposes.

Note:

The same basic tension brake parameters are used for the winch brakes. There are some differences such as the drum diameter remains constant.

Determining Torque Capacity…

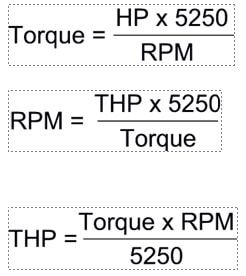

The following formulas are used to find the required torque capacity. Calculating the torque of a full roll and that at set stop is the same except for the difference in WK 2. and RPM.