Innovative, cutting-edge brake and clutch products for demanding industrial applications.

View ProductsSales Support

Industrial Clutch and Brake Systems

At Force Control, we offer the best selection of industrial clutch and brake systems on the market. Our industrial brake products include thruster brakes, mill motor brakes, electromagnetic brakes, pneumatic brakes, fail-safe brakes, clutch brakes, dynamometer brakes, tension brakes, oil shear technology products and more. Contact us today to learn more or get started!

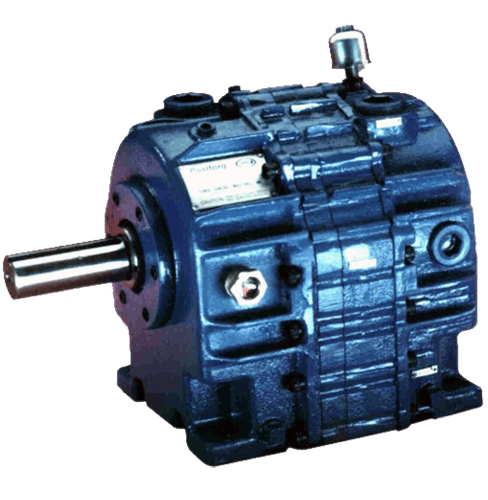

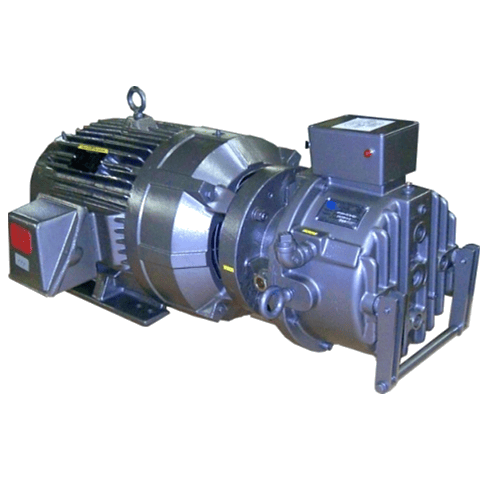

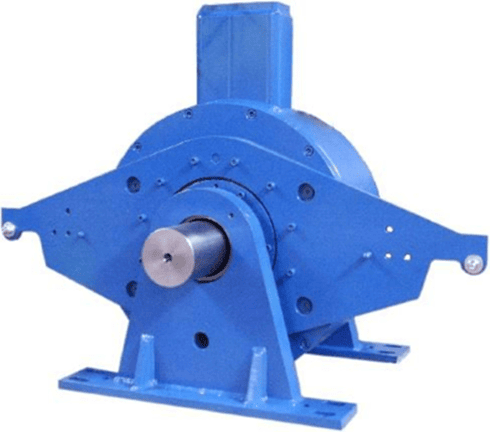

Posidyne® Pneumatic Clutch-Brakes

Posidyne Clutch Brakes offer reliable, maintenance free, high cycle indexing for severe duty applications in the steel, mining, food processing, marine, lumber and concrete industries.

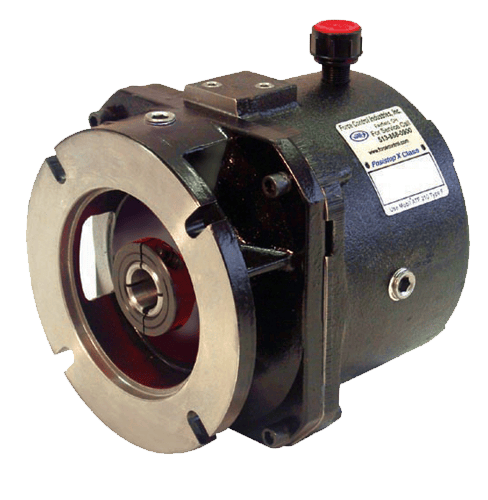

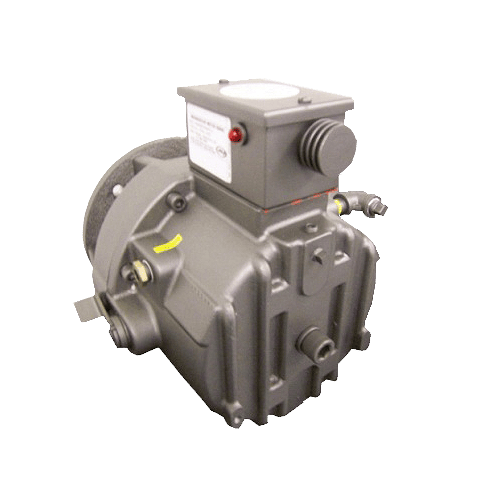

Posistop® Pneumatic Brakes

Posistop pneumatic brakes offer safe and reliable stopping. Foot mounted, C-face and coupler designs are ideal for severe duty applications such as food processing, packaging, and many more.

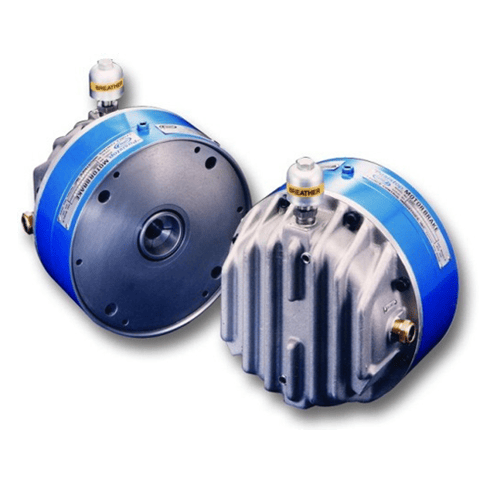

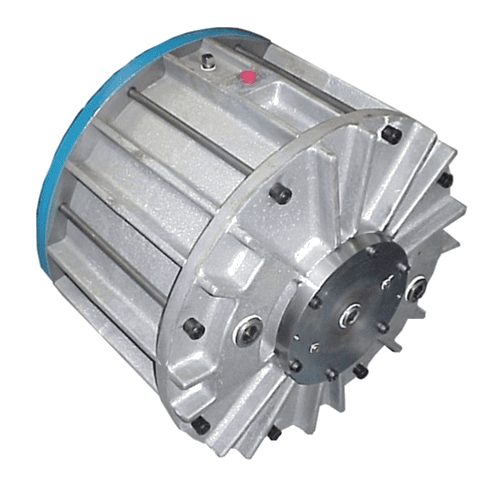

Magnashear® Electric Brakes

MagnaShear brakes are maintenance free and never need adjustment-ever! Designed where reliability is critical. Ideal for overhead cranes, marine winches and hoists, and conveyors.

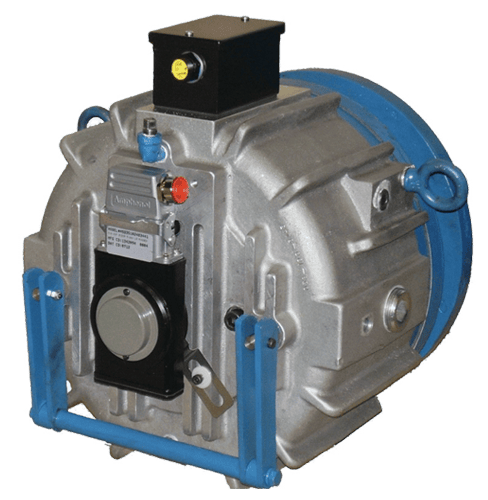

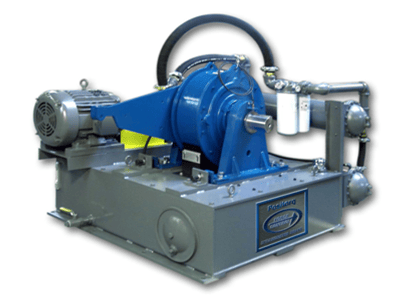

Positorq® Dynamic Load Brakes

Positorq brakes are designed for load absorbing applications such as tension control for unwinding applications. The brake and Forced Lube Cooling Unit provide a compact package.

Positorq load dynamometer brakes have been used worldwide for testing High-Torque loads at Low-Speed. Applications range from large torque wrenches to tractors, off road vehicles, military vehicles, helicopters, winches and much more.

Force Control is experienced in building complete dyno systems for high torque—low speed testing applications.

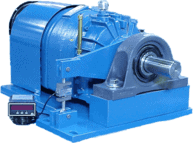

Dynamometers And Positorq Dynamometer Load Brakes

Positorq load brakes have been used worldwide for testing High Torque loads at Low Speed. Applications range from large torque wrenches to tractors, off road vehicles military vehicles, helicopters, winches and much more.

Force Control is experienced in building complete dyno systems for high torque—low speed testing applications.

We also offer options like thruster brakes, mill motor brakes, custom brakes for various industrial applications. These brakes provide reliable and consistent stopping power for different types of machinery and equipment.

Brake Motors, Clutches, and More

Industrial Oil Shear Technology Clutches & Brakes

Force Control Industries, Inc. manufactures superior quality, uniquely designed industrial clutches and brakes. Based on Oil Shear Technology, our industrial clutch and brake products provide superior life, as well as smooth operation and quicker response.

Force Control clutch and brake products are used on many types of machinery in the manufacturing of steel, coal, paper, concrete, brick, lumber, fiberglass, tires, automotive, wire, and many more. Please see our list of application bulletins for more information.

New to Force Control?

Learn how Force Control can help select, provide, and maintain cost saving clutches and brakes.

Read more...What is Oil Shear Technology?

The heart of all Force Control products it provides longer life, high cycle rates, smooth quiet operation.

Read more...Reduce Maintenance Cost

Learn how Force Control can reduce your maintenance purchasing and downtime cost.

Read more...Add Value to Your OEM Design

Learn how Force Control products can add value to your OEM machine by reducing maintenance.

Read more...Dynamometer Load Brakes

The Positorq dynamometer load brakes are ideal for high torque – low speed testing.

Read more...Industry Solutions

Review some of the applications where Force Control provided successful solutions.

Read more...Product Information

The Posidyne® clutch brake provides extremely long life and is an excellent choice for high cycle applications. Additionally, Posidyne® clutch brakes provide near servo accuracy in many applications. These clutch brakes are either pneumatically or hydraulically actuated, and furnished in several arrangements including C-face, shaft in – shaft out and piggyback mount.

Posistop® brakes come in several varieties such as motor mounted, double C-face, foot mounted, and hundreds of special mountings. Torque ranges from 50 Ft. Lbs. to 50,000 Ft. Lbs. Utilizing the same oil shear technology as the Posidyne® clutch brake, these brakes last longer, and engage smoother than the competition. Additionally, they can be used as stopping or holding brakes, with air, or hydraulic actuation, and spring set or pressure set. Many of the Posistop® brakes are interchangeable with Stearns®, Dings®, Warner®, Nexen® and many other brake manufacturers.

The MagnaShear® brake is an electrically released version of the Posistop® brake. Utilizing the same oil shear technology, it offers extreme life, and smooth engagement.

Positorq® brakes are designed to slip at a controlled torque (50 Ft. Lbs to 50,000 Ft. Lbs). These are used in tension applications (paper, steel, etc.) and energy absorbing applications such as dynamometers for testing transmissions, axles, shafts or other components. Our oil shear technology, designed for slip applications, is extremely smooth at low speeds, does not present the stick slip condition of many mechanical brakes, and has a very long wear life, including the drive plates and friction discs.

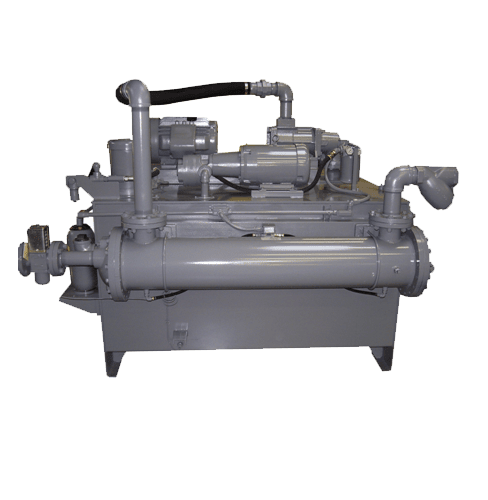

Hydrastop Thruster Brakes

At Force Control, we also offer an unmatched selection of Hydrastop thruster brakes for a variety of industrial applications. These brakes are designed to provide reliable stopping and holding power for equipment such as winches, conveyors, cranes, hoists, movable bridges and more.

All our Hydrastop thruster brakes are fully BABA-compliant, ensuring the highest level of safety for your workers and equipment. They are also precision crafted using high-quality materials to ensure long-lasting durability and efficiency.

Custom Design Services

For any of our products we offer at Force Control, our experienced engineers and technicians can provide custom design services for specific applications. They work closely with customers to understand the unique needs of each application, and then develop a solution that meets those needs while also providing reliable and long-lasting performance.

Our custom modifications are designed to fit special or old motors, mounting arrangements, space limitations and more. We can even manufacture complete custom drive packages that are ready to install immediately.

Service and support is our primary goal, so when you purchase a Force Control drive, not only does it last a long time, but you get superior support when rebuild or replacement is needed. Our Factory Certified Rebuild service will put your drive in like new condition reducing the chance of unnecessary repairs. Our Emergency Response Service (not for all products) has a unit shipping to you the same day. You then return the old core which is then rebuilt and put back into stock for the next emergency.

Contact Us

Our sales engineers are ready to help solve your drive application. Give us a call at 513-868-0900 or Email info@forcecontrol.com.