Posidyne Clutch Brakes for Heavy Duty, High Cycle Applications

- Torque: 518 LB-IN to 79,000 LB-IN

- HP: 1 HP to 1500 HP.

- Pneumatic or Hydraulic Actuation

- Cooling: Basic, Fan, Water and Forced Lube

- Optional C-Face or Piggyback Available

- Washdown, Marine Duty or Hazardous Duty

High Cycle—Up to 300 CPM

Long Life—5 to 10 Times Longer

Heavy Duty Totally Enclosed Housing

Torque Ratings from 500 LB-IN to 79,000 LB-IN – up to 1500 HP

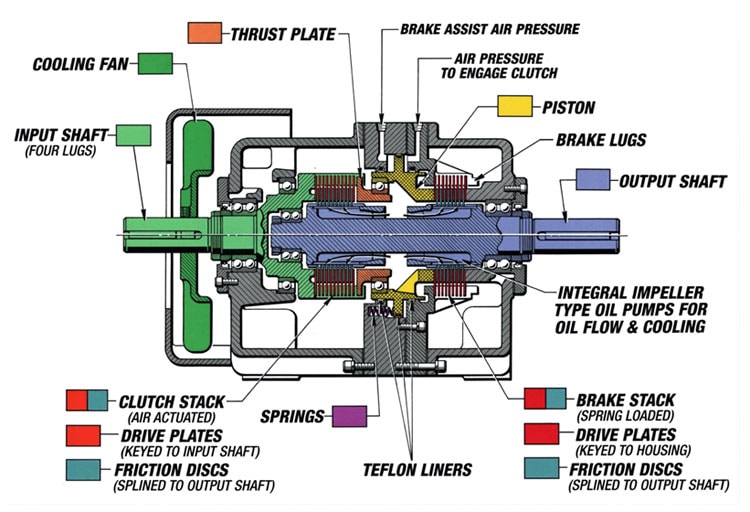

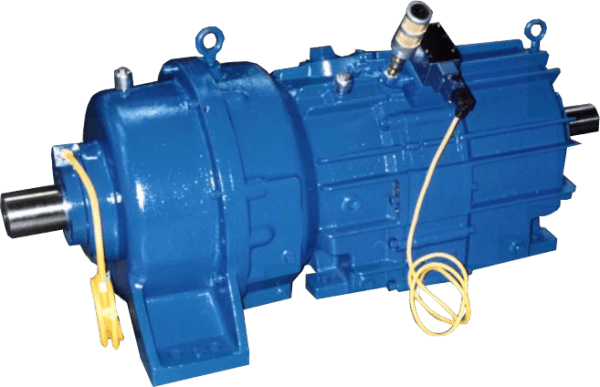

The foot mounted Posidyne Clutch Brake featuring Oil Shear Technology is oldest the most flexible clutch brake in the line. Beginning in 1969, thousands of Posidyne clutch brakes have been producing products around the world. Applications ranging from mining, lumber and steel to food processing, packaging and meat packing.

The Posidyne Clutch Brake is available in C-Face (smaller sizes), Long Coupled C face (C Face with coupling), Foot Mounted, and Piggy Back (mount the motor on top). The Posidyne comes as a clutch brake combination or clutch only. There are various operating logics which are the combination of a spring set brake or clutch or pressure set brake or clutch.

Cooling options include basic (radiant), fan cooled, water cooled, oil to air external cooling and forced lube cooling. Other options include manifold mounted valves, optical encoders, and many custom shaft styles (splined, metric, double keyway, etc.).

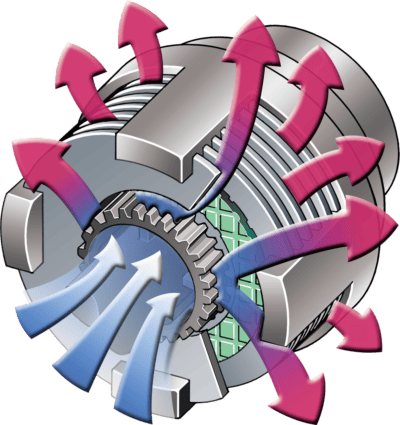

All Posidyne Clutch Brakes feature our world renowned Oil Shear Technology to eliminate regular maintenance, reduce cost, and increase production.

Oil Shear Technology – Reduces Maintenance Cost

- Air or Hydraulic Actuation

- Low Maintenance – Reduced Downtime

- Severe or Hazardous Duty

- Compact Size – High Thermal

- Washdown and Marine Duty Options

- Low Inertia Energy Savings

- Cooling – Basic, Fan, Water and Forced Lube

Typical Industry Applications Include:

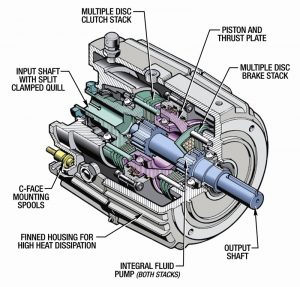

Posidyne Size 1.5 Clutch Brake with Lightweight Housing

- Torque: 518 LB-IN to 79,000 LB-IN

- HP: 1 HP to 1500 HP.

- Pneumatic or Hydraulic Actuation

- Cooling: Basic, Fan, Water and Forced Lube

- Optional C-Face or Piggyback Available

- Washdown, Marine Duty or Hazardous Duty

High Cycle—Up to 300 CPM

Long Life—5 to 10 Times Longer

Heavy Duty Totally Enclosed Housing

Designed for Food Processing and Packaging Applications

The Posidyne Clutch/Brake standard for performance and durability is available for your smaller 1/2 to 5 HP drives for conveyors, packaging machines, food processing applications and extruder cut-offs.

The size 1.5 Posidyne boosts the cycle rate (up to 300 CPM), accuracy, and life (20,000,000 – 40,000,000 cycles). They bring oil shear durability to a new level of performance and convenience in a compact, lightweight (aluminum housing), double C-Face mounted package.

The new split clamped quill input eliminates key and key-way problems associated with competitive clutch/brakes. The minimal inertia of cyclic parts, combined with high torque handling capability, puts more usable horsepower into your drive – quicker. The 1.5 Posidyne can cycle up to 300 times per minute, and with oil shear technology can last for years, making them perfect for those high cycle applications. High heat dissipation capability ensures long life and consistent accuracy in 24 hour operations. Convenient options such as foot mounting kits, manifold mounted valves and optical encoders are available to fit most any application.

Oil Shear Technology—300 Cycles per Minute

- Torque: 32 LB-IN to 427 LB-IN

- Pneumatic or Hydraulic Actuation

- Little-to-no Maintenace

- Higher Cycle Rates (up to 300 cpm)

- Lowest Cost per Index

- Severe or Hazardous Duty

- Washdown and Marine Duty Options

- Low Inertia Energy Savings

- Lightweight Compact Size

- Split Clamped Quill Shaft

- Foot Mounting Kit Available

Typical Applications include

- Packaging

- Food Processing

- Meat Packing

- Dynamite/Gun Powder

- Production Machines

- Automotive

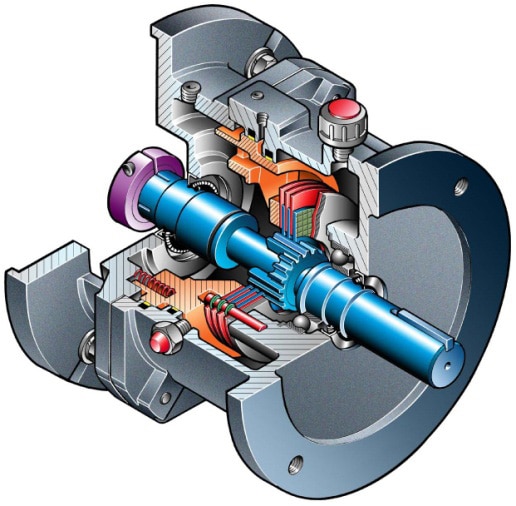

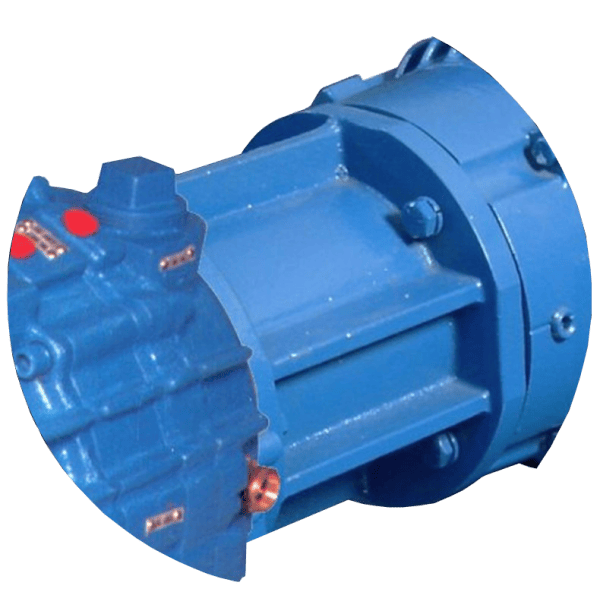

X-Class Posidyne

Oil Shear Technology – 5 to 10 Times Longer Life

- Value Engineered for OEM’s

- Pneumatic or Hydraulic Actuation

- Little-to-no Maintenance

- Lowest Cost per Index

- Washdown, Marine or Hazardous Duty

- Higher Cycle Rates (up to 300 cpm)

- C-Face: NEMA 56C to 256T

- Power Coated Cast Iron Housings

Typical Applications include;

Out Perform Competitive Clutch Brakes at a Lower Cost

Valued Engineered for the Highest Performance at the Lowest Cost per Cycle

The Posidyne® X Class Clutch/Brakes are designed and tested to operate over 20 million trouble free cycles with only occasional oil changes and no adjustment – ever! This unheard of life expectancy allows the Posidyne® X Class Clutch/Brakes to be used on applications previously thought impossible to do using a clutch/brake.

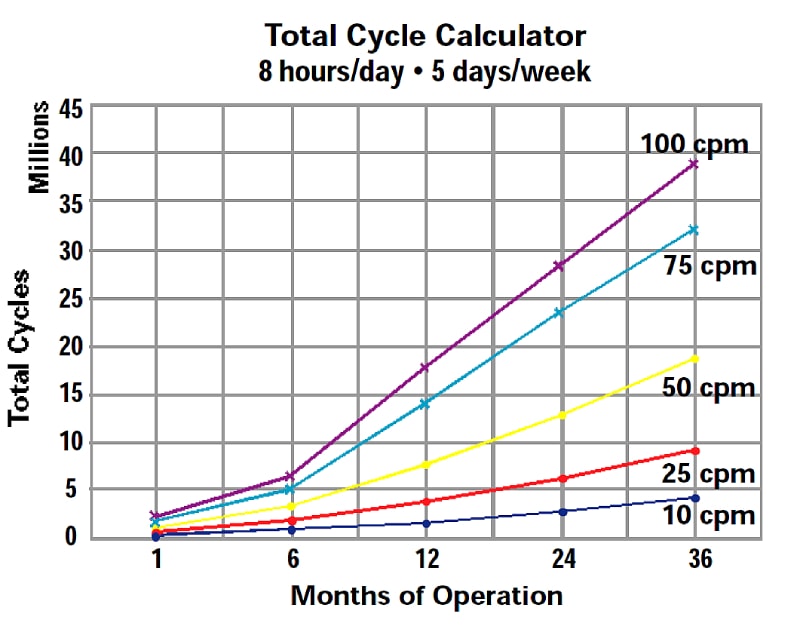

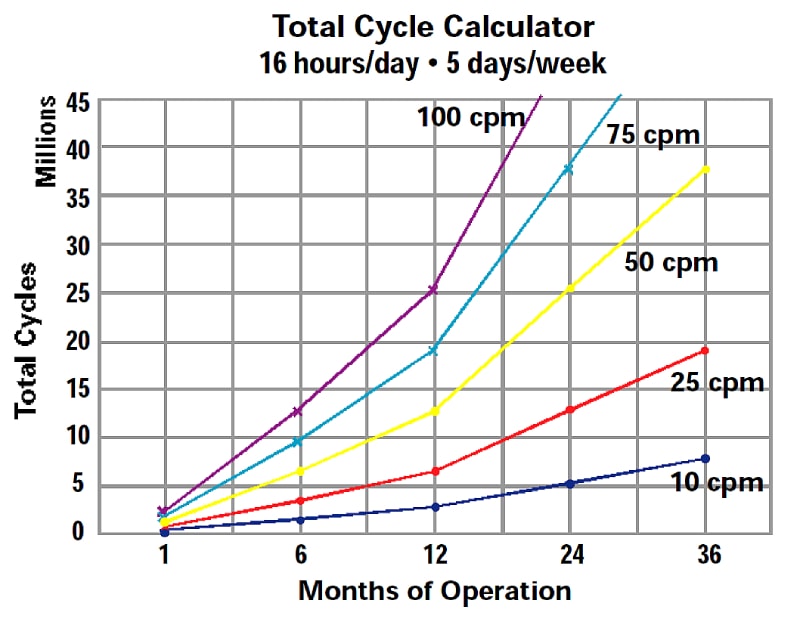

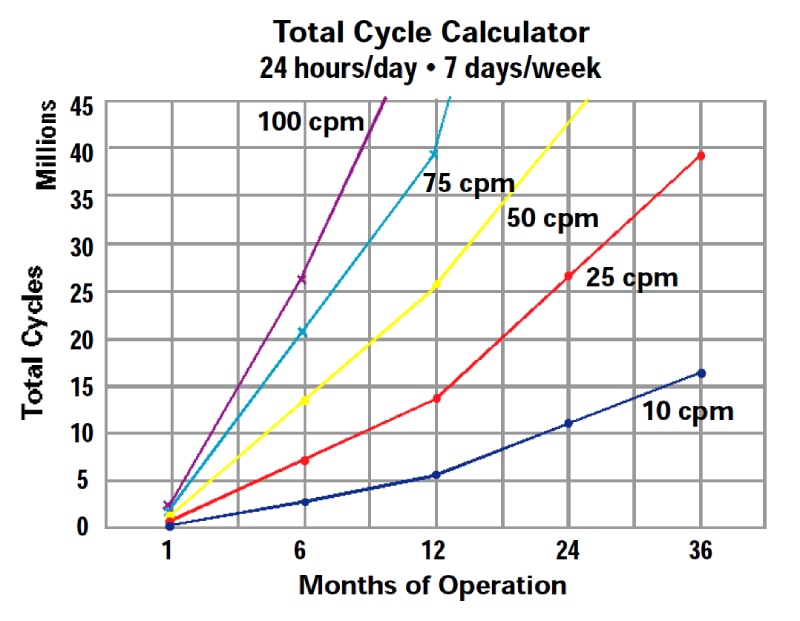

How many cycles do you require to meet your machines design life? Use the total Life Cycle Calculator shown below to determine expected life for your application.

The new Posidyne® X Class Clutch/Brakes let you eliminate the typical line stops, the frequent clutch/brake repairs and replacements. Here’s the reliability you need for today’s 24/7 manufacturing demands. Here’s speed and precision that can let you run at higher cycle rates and quality levels, or design new machines for higher performance.

The Posidyne X Class clutch brakes are value engineered that are affordable for OEM equipment builders providing top of the line equipment.

Value Engineered for OEM’s

No Adjustment – No Maintenance

Value Engineered for OEM’s

No Adjustment – No Maintenance

Clutch Brake Life Cycle Calculator

The Posidyne X Class clutch brakes are designed for maximum life with little to no maintenance. Especially when performing high cycles 100, 200, or ever 300 cycles per minute popular dry friction clutch brakes require constant adjustment repair and replacement. Many competitive units will only operate 1 million to maybe 5 million cycles, probably with some repair or adjustment. This number may be much lower in high cycle applications when heat will degrade the unit for early failure.

The Posidyne X Class clutch brakes are designed for 20 million to 40 million cycles and can handle the heat load of high cycle applications. Applications as high as 300 CPM operating 24/7 have been successful.

Use the Total Cycle Calculator below to determine the number of cycles for your operation.

POSIDYNE OPTIONS & ACCESSORIES

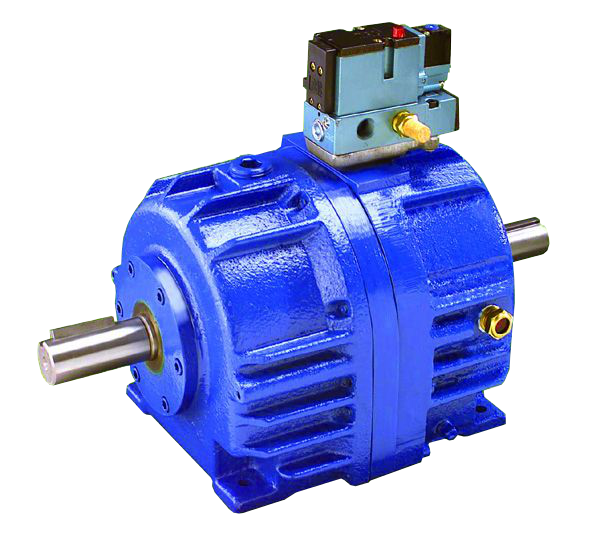

Posidyne Clutch/Brake with C-Face

Piggyback Posidyne

The Piggyback arrangement allows mounting the drive motor on top of the clutch brake where length is a problem. The package includes adjustable motor base, pulleys, guard, and motor (if desired). Piggyback is available for sizes 02 through 20.

Fan Cooled Units

Fan cooled Posidyne clutch/brake units may be required for those applications where higher cycle rates are requirements. The fan blows air across the housing increasing the thermal heat dissipation capability 3 to 5 times.

Water Cooled Units

Water cooling is available for those extremely high cycle, or high inertia load applications. An internal tubing coil is installed around the input shaft in the input housing. Water flowing through the tubing cools the internal transmission fluid during circulation.

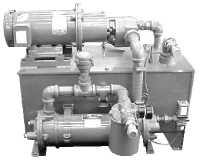

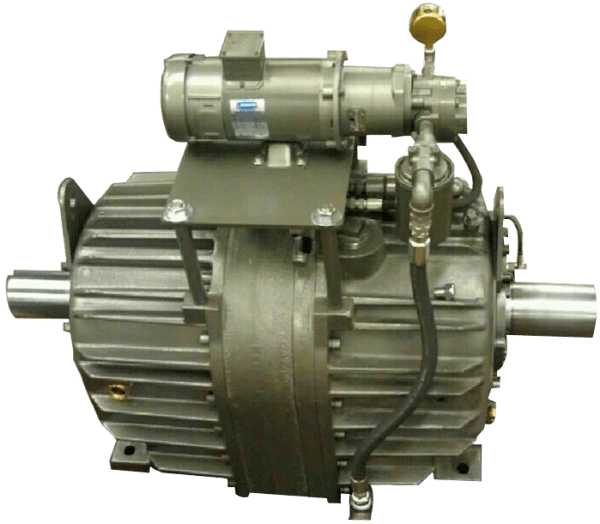

Oil-To-Air External Cooling

Transmission fluid is drawn out of the unit, circulated through an external oil-to-air heat exchanger (oil-to-water is available), through a filter and back into the unit. This system provides the ultimate life for the clutch brake in addition to handling extremely high thermal loads.

Forced Lube Cooling

Transmission fluid is pumped through the center of the output shaft, drawn out of the unit, circulated through an oil-to-water heat exchanger (oil-to-air is available), through a filter and back into the unit. This Forced Lube Cooling Unit system provides the ultimate heat dissipation continuous slip applications.

Posidyne Clutch/Brakes with Manifold Mounted Valve

The manifold mounted valve mounts directly on a machined surface on the Clutch Brake. This improves response time and positioning accuracy significantly by eliminating long hoses from the valve to the unit. It also reduces installation time and provides a cleaner package.

Washdown Duty for Food Processing Applications

All Posidyne Clutch brakes can be modified for washdown duty (USDA H-2) often found in food processing applications. Steel-It epoxy coatings on the housing, stainless steel fittings, nickel plated shafts, non corrosive breathers and sight gauge and bio-degradable fluid is included.

Posidyne Clutch/Brakes with Optical Encoder

Foot Mounting Kit

C-Face Long Coupled Input

Long Coupled C Face is available in Models 02, 2.5 and 03 with input for NEMA motor frame 143T to 256T. The long Coupled system uses a coupling, eliminating quill and keyway damage in high cycle, high load applications.

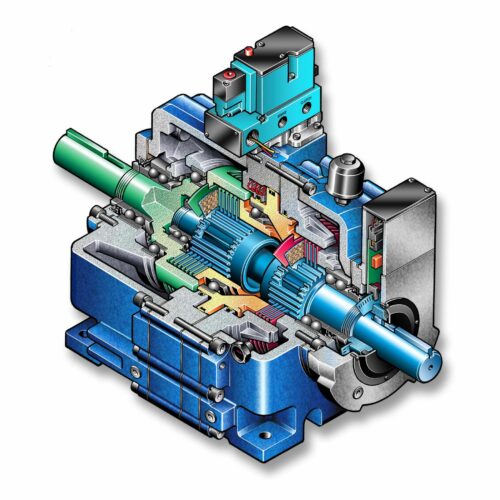

Integral Gearbox

In some cases the off the shelf gearboxes will not provide the load capability or reliability required for a high cycle, high load application. Force Control will design and build an integral gearbox as part of the clutch brake to handle the application and provide the long life expected.

Manifold Mounted Valve

The manifold mounted valve mounts directly on a machined surface on the Clutch Brake. This improves response time and positioning accuracy significantly by eliminating long hoses from the valve to the unit. It also reduces installation time and provides a cleaner package.

Marine Duty Modifications

All Posidyne Clutch brakes can be modified as marine duty. Modifications include Steel It epoxy coatings on the housing, stainless steel fittings, nickel plated shafts, and non corrosive breathers and sight gauge. Bio-degradable fluid is also included.