Challenges of Mining Operations

Mining operations are often located in remote areas with exposure to harsh weather, heavy loads, and constant vibration. These conditions demand strong, reliable braking systems that can perform under high stress while minimizing downtime and maintenance. Brakes in mining applications must be durable, capable of withstanding dust, moisture, and extreme temperatures without sacrificing safety or efficiency.

Heavy Duty Brakes for Mining Equipment

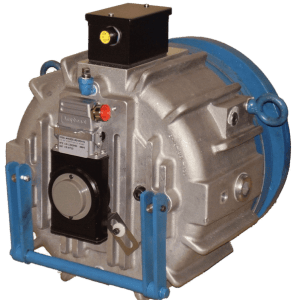

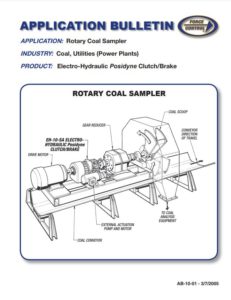

Mining machinery demands heavy duty brakes that can withstand extreme conditions while maintaining performance over long periods. Our braking solutions utilize Oil Shear Technology, which not only reduces wear but also enhances the overall lifespan of the equipment. With smooth, controlled stopping power, our systems are designed for high-torque, high-load applications where precision and reliability are critical.

For example, Posistop® Air/Hydraulic Motor Brakes are perfect for severe-duty applications where durability is essential. These brakes deliver excellent performance in high-stress environments, providing smooth stopping with minimal maintenance. Similarly, MagnaShear® Electric Brakes offer maintenance-free, spring-set brake systems that are ideal for continuous-duty operations, offering fast response times and reliable holding power for critical machinery.

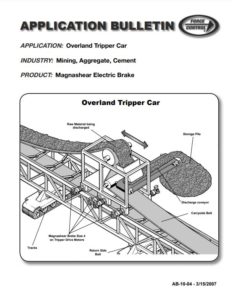

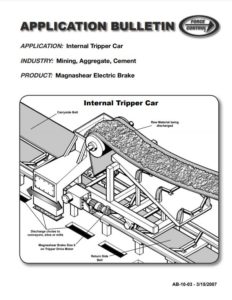

Tripper Car Brakes

Tripper car brakes play a crucial role in material distribution along conveyor systems. Accurate positioning is essential to ensure smooth operations and minimize downtime. Electric brakes are the most commonly used solution for these applications, and our MagnaShear® Brakes are a proven choice. These brakes deliver high torque to keep tripper cars securely positioned under load. Designed for demanding environments, MagnaShear brakes offer reliable performance, reduce maintenance requirements, and provide precise control for critical positioning tasks.

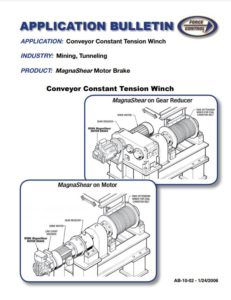

Conveyor Brakes

Conveyor systems are at the core of many mining operations, moving materials over long distances. Reliable braking is necessary to manage load control, prevent rollback, and stop the system when needed. MagnaShear® Motor Brakes are an ideal solution for these applications, offering a self-contained system that requires no adjustments. These conveyor brakes are built to handle the tough conditions of mining environments, offering dependability and ease of use. Their fail-safe design ensures the conveyor system will operate smoothly and safely, even under the most challenging conditions.

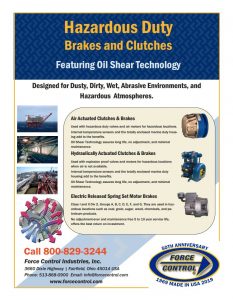

Hazardous Duty Brakes

Mining environments often involve explosive dust or gases, requiring specialized hazardous duty brakes that meet hazardous duty standards. Our brakes, including Posistop® Brakes and MagnaShear® MHD Series Brakes, are engineered for hazardous environments. Posistop® Brakes are suitable for Class I, II, and III, Divisions 1 and 2, offering strong protection in explosive atmospheres. MagnaShear® MHD Series Brakes are rated for Class I and II, Division 2 Only, providing reliable performance in less severe hazardous locations. Both brake types are designed to enhance safety and reliability, ensuring compliance with strict safety regulations in demanding industrial settings.

The MagnaShear® MHD Series is now CSA certified, it has been tested and verified to meet recognized safety standards in North America. This certification offers added confidence in the brake’s safety, reliability, and suitability for hazardous industrial applications.

Contact Us

For more information about our mining solutions, contact us today. Our team is ready to help you select the right products for your operations and make sure your equipment performs at its best, no matter the conditions.