Overhead cranes play a crucial role in lifting and moving heavy loads across factories, warehouses, and industrial sites. These cranes, also known as EOT (Electric Overhead Traveling) cranes, rely on dependable components to operate safely and efficiently. One essential component that demands attention is the holding brake.

Force Control provides fail-safe holding brakes for today’s overhead crane industry. The key drivers of the industry are safety and reliability and Force Control products are designed to exceed these expectations. Force Control’s products, featuring, Oil Shear Technology, offer a 5-10x longer service life with no down time or maintenance. Our spring set, electrically or pneumatically released brakes are semi-customizable to fit any application. Retrofit your Dings® Stearns®, Warner® or Nexen® dry-friction brakes today!

Why Holding Brakes Matter for Overhead Cranes

Holding brakes serve a vital function on overhead cranes by preventing unintended movement when the crane is at rest or carrying a load. These brakes keep the crane stable and secure, especially during power outages or emergency stops. Without reliable holding brakes, the risk of accidents and damage increases substantially.

Our holding brakes provide consistent performance that operators and maintenance teams can trust. Our patented Oil Shear Technology sets us apart by allowing the brake to engage without sacrificing friction material each cycle all the while transferring heat away from internal components, which greatly reduces wear. This means holding brakes on overhead cranes last significantly longer than traditional dry-friction brakes and require far less maintenance.

Product Range Built for Crane Safety and Efficiency

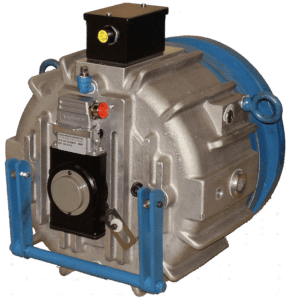

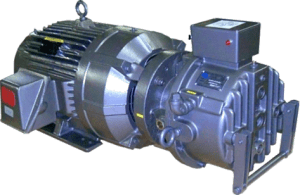

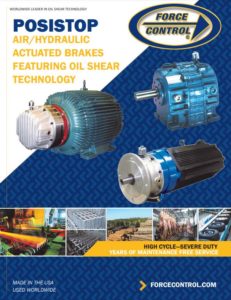

Force Control offers several holding brake models suitable for overhead cranes. The MagnaShear Motor Brakes feature a spring-set, electric-release design ideal for dynamic stopping in hoists and cranes. Posistop Brakes offer spring-set designs with air or hydraulic releases, fitting motor, coupler, and servo applications.

Hydrastop electrohydraulic drum brakes also offer dependable, fail-safe holding for crane bridge and trolley drives. Their spring-set, thruster-released design guarantees consistent performance even during power loss. Built with corrosion-resistant components and IP66-rated thrusters, they deliver long service life with minimal maintenance.