Force Control C Face Uses Split Clamped Quill Shaft Connection

Split Clamped Quill Shaft Connection Reduces Motor Shaft and Keyway Damage

Many Force Control Industries clutches and brakes are available for C Face mounting. C Face means the clutch or brake can be mounted to a motor or gear reducer by a flange mounting and female quill to male shaft extension. Many applications have the motor C Faced to the clutch brake or brake and the clutch or brake is then C Faced to the gear reducer. This mounting system eliminates installing couplings and the ongoing alignment issue plus another part to be maintained.

There are several C Face mounting standards. One of the most common is NEMA (National Electric Manufacturers Association) standards which is the standard for Force Control C Face products. IEC is an international standard and some products have been modified to fit the IEC standard.

C Face connections are great for compact drive arrangements and simple installation when connecting motors to clutches, clutch brakes or brakes, and to gear reducers, however there are some issues that can cause serious problems. With a C Face connection the motor shaft typically slides into a hollow quill in the brake or clutch brake. A key and keyway are used to prevent rotation between the shaft and quill. This means that the fit must be loose enough for simple installation or removal.

The problem is with a clutch or brake there is a torque reversal for every start and stop. When connecting this type of application it is typically recommended that a tight fit between components is provided to provide holding power around the shaft and eliminate transferring the torque exclusively through the key.

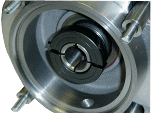

To solve this problem Force Control Industries, Inc. designed the Split Clamped Quill. The quill itself is saw cut in four locations at 90 degrees around the diameter with one over the keyway. A Clamp collar is installed over the diameter of the quill. When tightened this applies a 360 degree connection around the shaft reducing the load on the key.

This system allows the shaft/quill connection to be loose during installation or removal. After assembly the clamp collar is tightened. To remove, loosen the clamp collar and the shaft is again loose and can be removed easily.

The Split Clamped Quill is used on the Posidyne size 1.5, all X Class clutch brakes, motor brakes, and coupler brakes, and some MagnaShear motor brakes and coupler brakes.