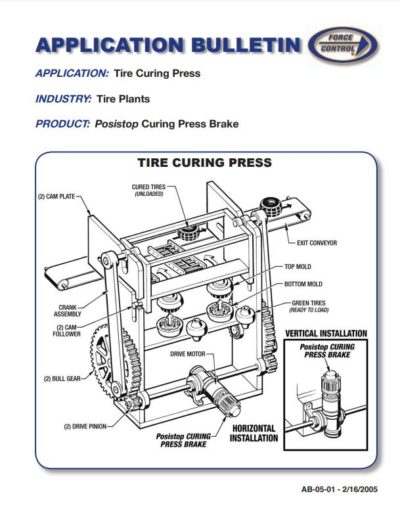

Force Control’s tire curing press brake is maintenance-free and adjustment-free. The Posistop® CPB is a direct fit-in replacement to the currently used dry friction brakes mounted on the back of a motor used to open and close the McNeil NRM press for tire manufacturing and retreading operations. The totally-enclosed Posistop CPB features Oil Shear Technology that eliminates all of the maintenance aspects of the dry friction brakes, including wear which leads to adjustment and replacement.

Currently installed dry friction brakes generate heat which degrades the friction material, reducing torque (glazing), and eventually failure. To make up for reduced torque due to wear on the friction plates, the brakes require frequent adjustment. If not adjusted, the coils will not release the brake, causing serious damage to the brake, or the motor. If brake torque fades too much, the stop will miss-position, causing serious press damage. Constant actuation coupled with moisture and heat also cause the brake coil to fail. The numerous small linkages within the brake will corrode due to moisture, humidity, and chemical fumes causing the brake to hang up, yielding engagement and disengagement problems.

In contrast, the totally-enclosed, sealed Posistop CPB keeps automatic transmission fluid in and the dirt, oil, moisture, and chemical fumes out, eliminating those problems. During engagement, a thin film of transmission fluid between a series of friction discs and drive plates transmits torque. Because most of the work is done by the fluid molecules in shear, wear is virtually eliminated as is the need for adjustment. As the pressure on the disc stack reaches a static condition, the brake becomes a static holding brake.

Heat, which causes many problems in dry braking systems, is eliminated by the transmission fluid which is circulated through the disc stack and back to the housing. Heat generated in the friction stack during stopping is carried to the housing to be cooled. The cooled fluid is then directed back into the stack to repeat the process. Since the transmission fluid acts as a lubricant, the bearings and splines are constantly lubricated, eliminating wear and early failure on these components.

The spring-set, pneumatically released Posistop brake is better suited to the wet, hot conditions typically found in tire press brake operations than electrical components used in dry braking. The air tends to cool, whereas electric actuation generates its own internal heat. The unique air-actuated piston system is designed to seal the piston for a long, maintenance-free service life. In addition to the high-temperature O-rings used to seal the piston, Teflon liners are installed over the O-rings to keep them from rolling up and breaking. A heavy-duty, cast iron housing sealed with Viton high-temperature seals is designed for industrial usage providing years of service before rebuild. A pre-plumbed and mounted air valve (460 VAC, 115 VAC or 24 VDC) is included for quick response.

The CPB brake comes fully assembled, filled with fluid, and ready to install. The bore has been pre-coated with Never-Seize to assist in brake removal if ever needed, and the included jack bolts assist in removing the cover and removing the brake from the motor.

Key Benefits of the Posistop CPB

- Maintenance-Free & Adjustment-Free – Eliminates the frequent servicing required by dry friction brakes, reducing downtime.

- Extended Service Life – Oil Shear Technology prevents wear, minimizing the need for replacements.

- Superior Heat Dissipation – Transmission fluid absorbs and dissipates heat, preventing brake fade and component failure.

- Sealed & Enclosed Design – Protects against dirt, moisture, and chemical exposure, ensuring consistent performance in demanding environments.

- Reliable in Harsh Conditions – Pneumatic actuation withstands wet, hot conditions better than electric systems, with built-in cooling properties.

- Quick & Simple Installation – Pre-assembled, fluid-filled, and ready to mount, with included jack bolts for easy removal when needed.

The Posistop CPB enhances reliability, eliminates costly adjustments, and extends the lifespan of curing press brake systems, making it a superior replacement for traditional dry friction systems like the Stearns brake.

Break the Cycle with Force Control Industries, Inc.

Upgrade your tire curing press brake with the maintenance-free reliability of the Posistop CPB. Say goodbye to frequent adjustments, overheating, and premature wear—our curing press brake solution guarantees long-lasting performance in the most demanding environments. Designed as a direct replacement for outdated systems like the Stearns brake, the Posistop CPB improves efficiency and reduces downtime. Contact us today to learn how this advanced braking technology can enhance your McNeil NRM press or tire press brake operations. Maximize productivity with a solution built for durability and performance!