The Food & Beverage Processing Industry is always looking for reliable solutions to meet increasing challenges of the food processing environment. Force Control offers a wide range of solutions specifically designed for the high standards of the food industry. Our totally enclosed, oil-immersed clutches and brakes are available in washdown duty to combat caustic washdowns.

We offer nickel-plated shafts, nickel-plated housings or Steel-It® epoxy-coated housings and corrosion resistant components to combat the harsh environmental conditions and caustic cleaning agents. Synthetic food grade (USDA H-2) transmission fluid is used to meet food production compliance. You can rely on Force Control products to provide years of trouble-free service with little to no maintenance over the life of the product.

The Importance of Specialized Brakes in Food Processing

Food processing facilities operate under demanding conditions, requiring food processing equipment brakes that has efficiency, safety, and compliance with strict sanitation standards. Equipment in these environments is subject to frequent caustic washdowns, high humidity, and continuous operation, making corrosion resistance and reliability essential. Standard brakes may fail under these conditions, leading to downtime and costly maintenance.

Our food safe brakes and caustic washdown clutch-brakes are specifically engineered to withstand harsh cleaning agents, prevent contamination, and maintain consistent performance. Designed for longevity and minimal maintenance, these braking solutions help keep production lines running smoothly while ensuring food safety and regulatory compliance.

Product Range for Food Processing Equipment

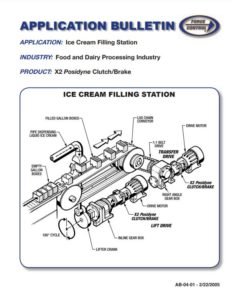

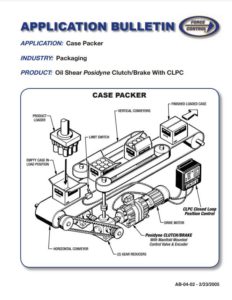

Posidyne® Clutch-Brakes

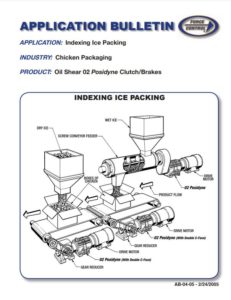

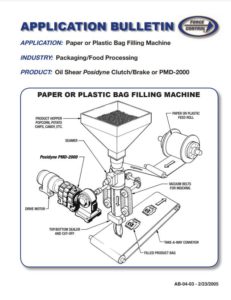

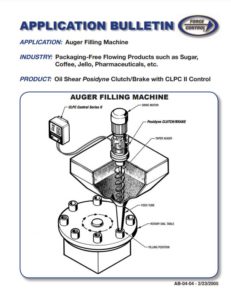

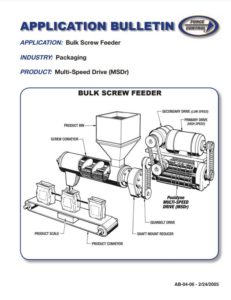

Posidyne® Clutch-Brakes provide precise, high-cycle motion control using oil shear technology, to have smooth engagement, reduced wear, and long service life. Ideal for food processing, material handling, and automated systems, these food safe clutch-brakes eliminate downtime and maintenance costs while delivering consistent performance in high-speed, repetitive applications.

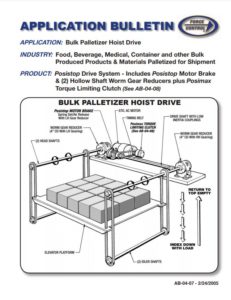

Posistop® Pneumatic Brakes

Posistop® Pneumatic Brakes offer fail-safe stopping power with a spring-set, air-released design, ensuring safety and reliability in packaging, conveyors, and automation. Available in foot-mounted, C-face, and coupler configurations, these food-safe brakes deliver low-maintenance, high-performance braking for industrial applications requiring smooth operation, minimal shock loading, and durable, long-term use.

MagnaShear® Electromagnetic Brakes

MagnaShear® Electromagnetic Brakes provide maintenance-free electric braking with oil shear technology, having consistent, wear-free performance in cranes, hoists, and bulk handling systems. Designed for harsh environments, these food-safe brakes operate reliably in wet, dirty, or extreme conditions, eliminating common wear issues found in traditional electric brakes while enhancing safety and efficiency.

Supporting Products for Enhanced Operations

In addition to our core braking solutions, we offer a range of complementary products to further support your food processing operations:

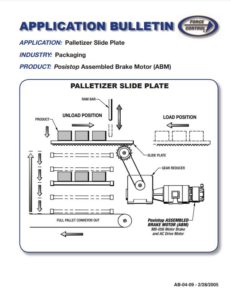

- Brake Motors: Guarantee smooth and efficient operation, reducing downtime.

- Force Control ATF Type F: Specialty fluid for optimal lubrication and protection.

Ready for the Toughest Conditions? Our Products Are

By selecting Force Control Industries’ solutions for your food processing operations, you gain access to products that are designed with durability, safety, and efficiency in mind. Our food-safe brakes, nickel-plated clutch-brakes, and caustic washdown brakes help reduce maintenance costs, improve operational reliability, and maintain compliance with food safety regulations.

For more information on how Force Control Industries can support your food processing operations, please contact us. We’re here to help and assist you in selecting the right braking solutions to meet your specific needs.