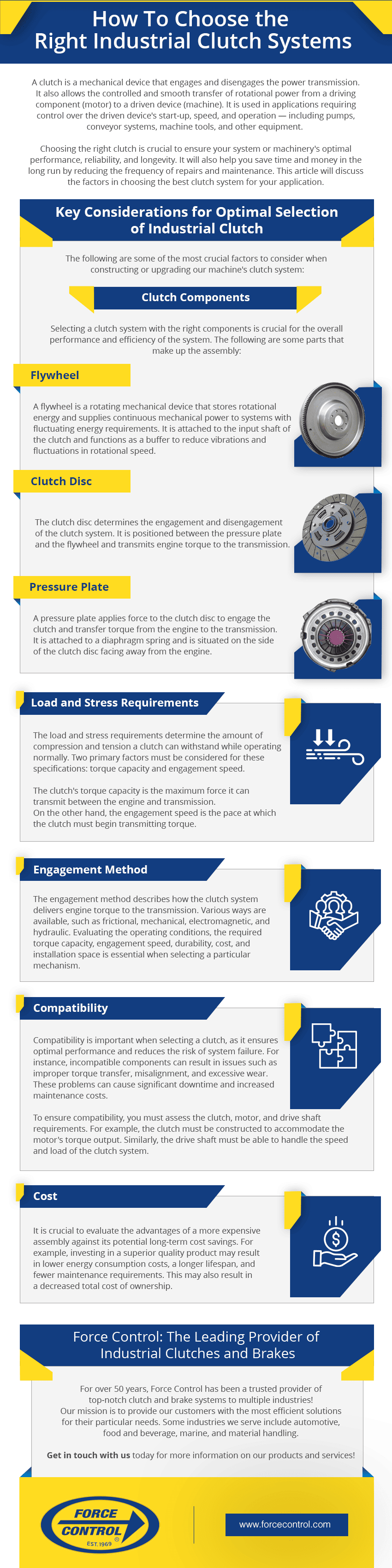

A clutch is a mechanical device that engages and disengages the power transmission. It also allows the controlled and smooth transfer of rotational power from a driving component (motor) to a driven device (machine). It is used in applications requiring control over the driven device’s start-up, speed, and operation — including pumps, conveyor systems, machine tools, and other equipment.

Choosing the right clutch is crucial to ensure your system or machinery’s optimal performance, reliability, and longevity. It will also help you save time and money in the long run by reducing the frequency of repairs and maintenance. This article will discuss the factors in choosing the best clutch system for your application.

Key Considerations for Optimal Selection of Industrial Clutch

The following are some of the most crucial factors to consider when constructing or upgrading our machine’s clutch system:

Clutch Components

Selecting a clutch system with the right components is crucial for the overall performance and efficiency of the system. The following are some parts that make up the assembly:

Flywheel

A flywheel is a rotating mechanical device that stores rotational energy and supplies continuous mechanical power to systems with fluctuating energy requirements. It is attached to the input shaft of the clutch and functions as a buffer to reduce vibrations and fluctuations in rotational speed.

Clutch Disc

The clutch disc determines the engagement and disengagement of the clutch system. It is positioned between the pressure plate and the flywheel and transmits engine torque to the transmission.

Pressure Plate

A pressure plate applies force to the clutch disc to engage the clutch and transfer torque from the engine to the transmission. It is attached to a diaphragm spring and is situated on the side of the clutch disc facing away from the engine.

Load and Stress Requirements

The load and stress requirements determine the amount of compression and tension a clutch can withstand while operating normally. Two primary factors must be considered for these specifications: torque capacity and engagement speed.

The clutch’s torque capacity is the maximum force it can transmit between the engine and transmission. On the other hand, the engagement speed is the pace at which the clutch must begin transmitting torque.

Engagement Method

The engagement method describes how the clutch system delivers engine torque to the transmission. Various ways are available, such as frictional, mechanical, electromagnetic, and hydraulic. Evaluating the operating conditions, the required torque capacity, engagement speed, durability, cost, and installation space is essential when selecting a particular mechanism.

Compatibility

Compatibility is important when selecting a clutch, as it ensures optimal performance and reduces the risk of system failure. For instance, incompatible components can result in issues such as improper torque transfer, misalignment, and excessive wear. These problems can cause significant downtime and increased maintenance costs.

To ensure compatibility, you must assess the clutch, motor, and drive shaft requirements. For example, the clutch must be constructed to accommodate the motor’s torque output. Similarly, the drive shaft must be able to handle the speed and load of the clutch system.

Cost

It is crucial to evaluate the advantages of a more expensive assembly against its potential long-term cost savings. For example, investing in a superior quality product may result in lower energy consumption costs, a longer lifespan, and fewer maintenance requirements. This may also result in a decreased total cost of ownership.

Force Control: The Leading Provider of Industrial Clutches and Brakes

For over 50 years, Force Control has been a trusted provider of top-notch clutch and brake systems to multiple industries! Our mission is to provide our customers with the most efficient solutions for their particular needs. Some industries we serve include automotive, food and beverage, marine, and material handling.

Get in touch with us today for more information on our products and services!